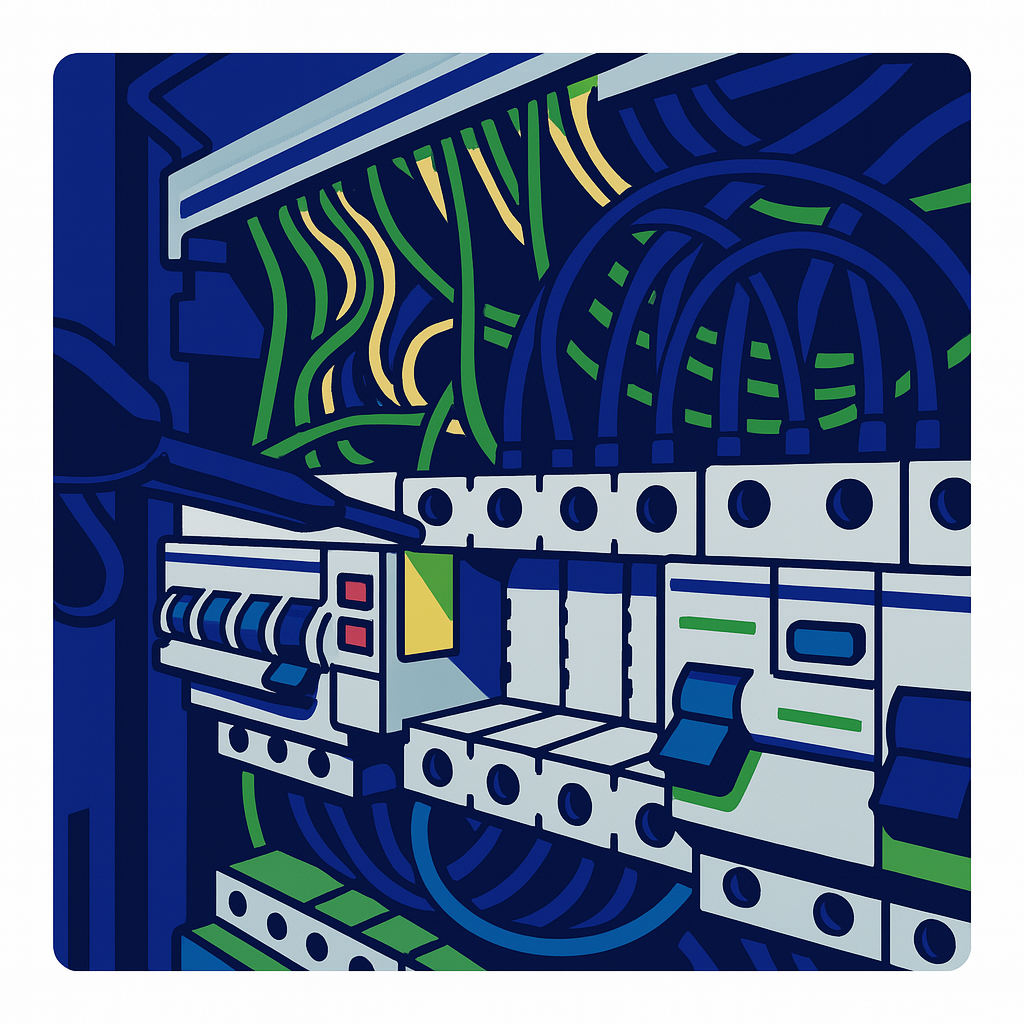

Overview of electrical components

Understand the different electrical and automatic components used for regulation, control, hydraulic operation and communication in lifts and lifting equipment, becoming familiar with their functions and characteristics according to the type of installation.

Preventive and corrective maintenance

Train participants to carry out preventive and corrective maintenance tasks on electrical components, following technical documentation and maintenance schedules to ensure reliable operation and extend equipment service life.

Inspection and diagnosis of electrical and automatic systems

Inspect the condition and integration of electrical, hydraulic and data transmission systems, using drawings, technical specifications and approved assembly methods, completing maintenance records and applying the appropriate safety measures.

Effective troubleshooting

Prepare participants to quickly identify the most common faults in electrical and automatic control systems, using systematic analysis methods and diagnostic tools to locate and resolve problems efficiently.

Repair and replacement of electrical components

Repair or replace defective or incompatible electrical and automatic components, ensuring compatibility between parts, carrying out safety and functional tests, and documenting each intervention in line with quality procedures.

Compliance with safety and quality requirements

Apply all relevant health and safety measures in lift installation and maintenance activities, ensuring functional quality and regulatory compliance in every maintenance or repair action.