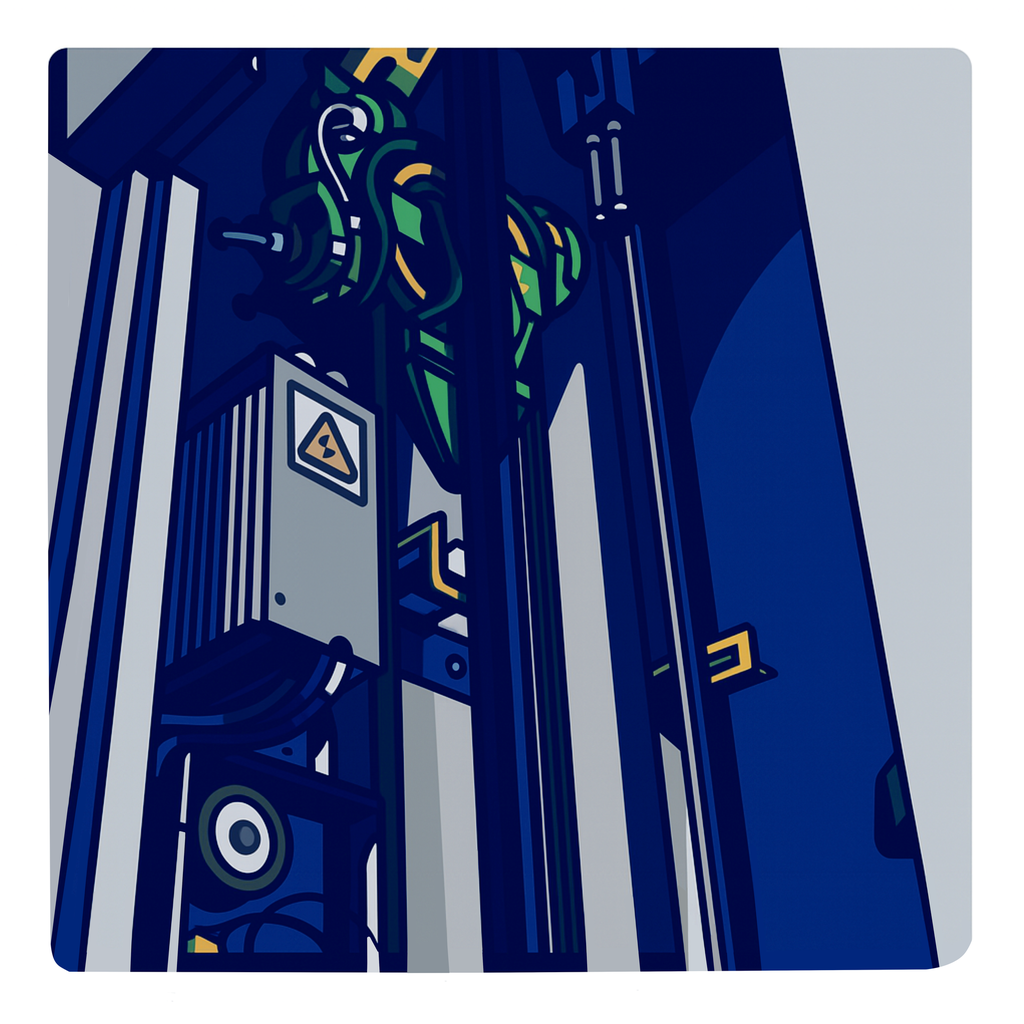

Overview of variable frequency drive (VFD) systems

Understand the principles and applications of variable frequency drives used in lift motors, including electromechanical lifts, hydraulic systems, and auxiliary components such as automatic doors.

Compliance with safety and quality requirements

Apply all relevant health and safety measures specific to lift construction and installation during maintenance and repair activities, ensuring regulatory compliance and functional quality of the system.

Repair of control systems

Repair or replace defective electrical and automatic control components, ensuring compatibility between components, carrying out safety and functional tests, and documenting each intervention in accordance with quality standards.

Diagnosis of electrical and automatic systems

Detect and locate faults in regulation and control systems (mechanical, hydraulic, communications and data transmission), using drawings, technical specifications and approved assembly methods, and completing maintenance programme records.

Specialised preventive maintenance

Carry out periodic inspections related to operation, wear, cleaning and adjustment of components and assemblies, following technical documentation and maintenance schedules in order to correct deviations and extend equipment service life.