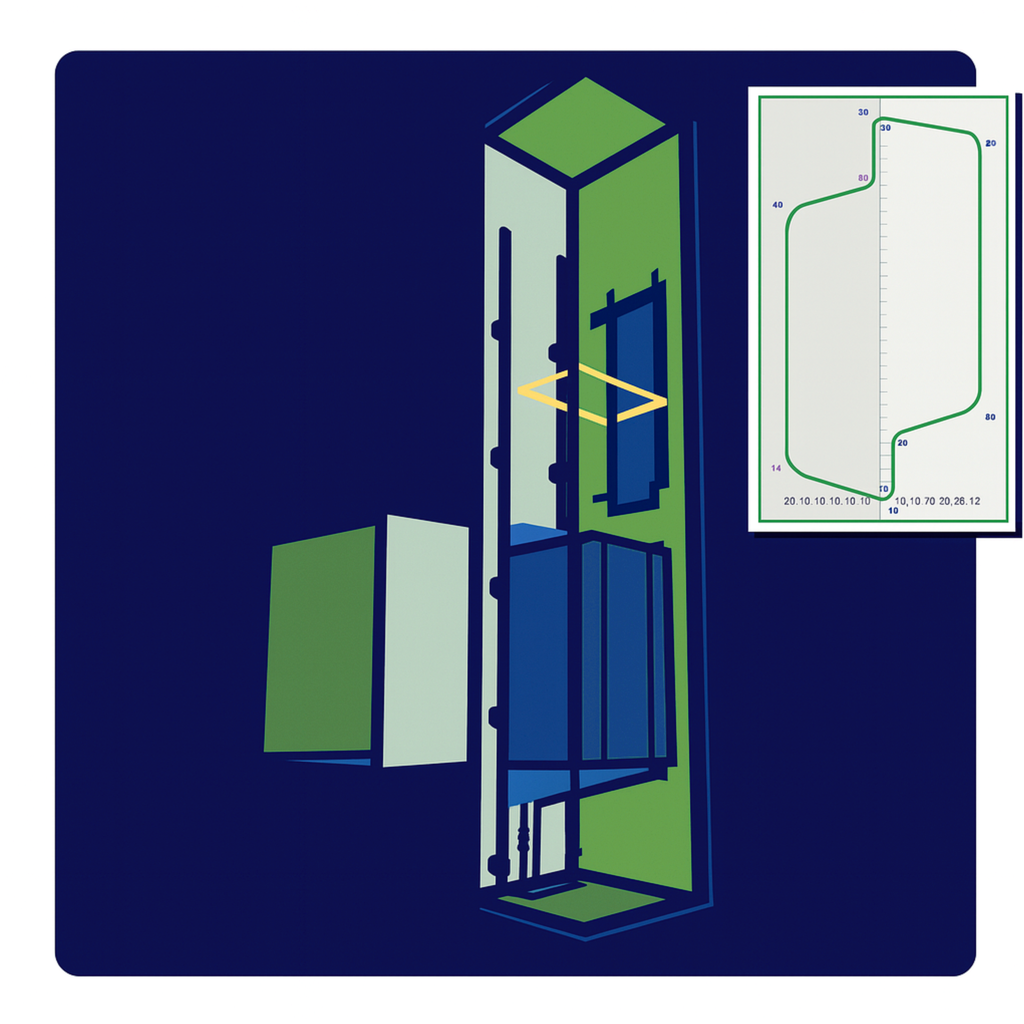

Fundamental concepts of hydraulic components

Understand the construction, functions, and types of hydraulic components used in lifts and lifting equipment.

Operation of the valve block

Understand the role and operation of valves in controlling flow and pressure within the hydraulic system.

Immediate practical simulation

Transfer theoretical knowledge into a virtual environment that allows safe practice of checks, adjustments, and repairs without risk.

Repair and commissioning

Replace or add mechanical and hydraulic components, ensuring compatibility and carrying out safety and functional tests to restore required performance and safety levels.

Comprehensive system diagnostics

Identify mechanical and hydraulic faults using drawings, technical specifications, and certified assembly methods, completing maintenance programme records accurately.

Detection and repair of hydraulic faults

Quickly identify failures in pipes, seals, and valve blocks, and apply safe procedures for effective correction.

Optimisation of preventive checks on mechanical and hydraulic systems

Carry out periodic inspections for wear, cleaning, and lubrication of hydraulic circuits to anticipate potential performance deviations.

Adjust components and assemblies in line with technical documentation and maintenance programmes, applying health and safety measures and ensuring quality in corrective actions.